- Corrosion resistance.

- Long life.

- After Sales Support.

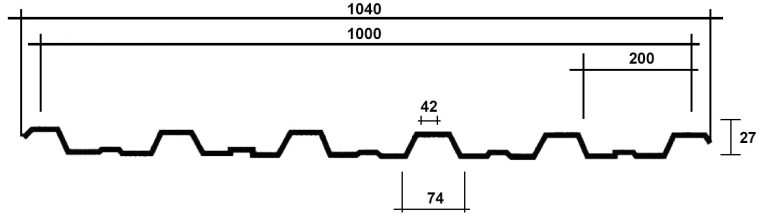

| Thickness | 0,30mm - 1,20mm |

| Size | 1000mm – 14000mm |

| Clear Closur | 800mm - 1000mm |

| Purlin Spacing (mm) | Galvanized Sheet Thickness (mm) | ||||||

| 0,50 | 0,60 | 0,70 | 0,80 | 0,90 | 1,00 | 1,20 | |

| 1,20 | 411 | 536 | 617 | 107 | 182 | 824 | 989 |

| 1,40 | 302 | 393 | 453 | 515 | 575 | 605 | 726 |

| 1,50 | 264 | 343 | 396 | 449 | 501 | 528 | 634 |

| 1,80 | 183 | 238 | 275 | 312 | 348 | 367 | 440 |

| 2,00 | 149 | 193 | 223 | 252 | 282 | 297 | 356 |

| 2,20 | 123 | 160 | 184 | 209 | 233 | 245 | 295 |

| 2,40 | 103 | 134 | 155 | 175 | 186 | 206 | 248 |

| 2,80 | 95 | 98 | 114 | 129 | 144 | 152 | 182 |

| 3,00 | 66 | 86 | 99 | 112 | 125 | 132 | 158 |

| Moment of Inertia (j:cm4/m) | 6,71 | 8,73 | 10,07 | 11,41 | 12,75 | 13,43 | 16,11 |

| Strength Moment (W:cm3/m) | 3,48 | 5,03 | 5,80 | 6,58 | 7,35 | 7,74 | 9,29 |

Allowable Stress = 1200 kg/cm2. Calculations are based on continuous beam shape.

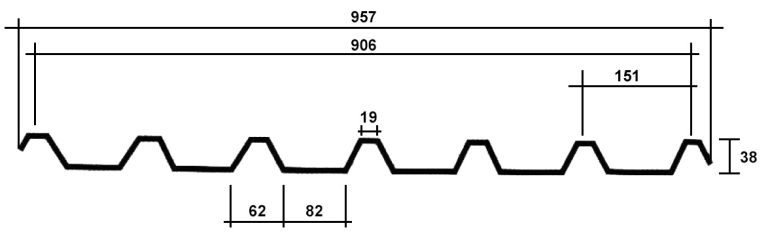

| Purlin Spacing (mm) | Galvanized Sheet Thickness (mm) | ||||||

| 0,50 | 0,60 | 0,70 | 0,80 | 0,90 | 1,00 | 1,20 | |

| 1,20 | 460 | 555 | 643 | 730 | 817 | 901 | 1068 |

| 1,40 | 342 | 408 | 472 | 537 | 600 | 662 | 785 |

| 1,50 | 262 | 312 | 362 | 411 | 459 | 507 | 601 |

| 1,80 | 207 | 247 | 286 | 325 | 363 | 401 | 475 |

| 2,00 | 168 | 200 | 231 | 263 | 294 | 325 | 385 |

| 2,20 | 138 | 165 | 191 | 217 | 243 | 268 | 318 |

| 2,40 | 116 | 139 | 161 | 183 | 204 | 225 | 267 |

| 2,80 | 99 | 118 | 137 | 156 | 174 | 192 | 228 |

| 3,00 | 67 | 80 | 93 | 105 | 118 | 130 | 154 |

| Moment of Inertia (j:cm4/m) | 12,79 | 15,24 | 17,66 | 20,05 | 22,40 | 24,72 | 29,27 |

|

Strength Moment (W:cm3/m) |

5,08 | 6,05 | 7,02 | 7,97 | 8,91 | 9,83 | 11,65 |

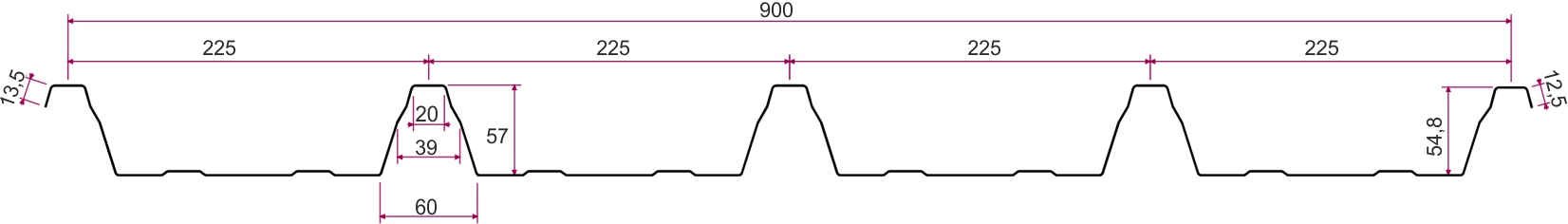

| Purlin Spacing (mm) | Galvanized Sheet Thickness (mm) | ||||||

| 0,5 | 0,5 | 0,7 | 0,8 | 0,9 | 1 | 1,2 | |

| 1 | 1.464 | 1.753 | 2.040 | 2.327 | 2.613 | 2.897 | 3.462 |

| 1,5 | 651 | 779 | 907 | 1.034 | 1.161 | 1.288 | 1.539 |

| 2 | 366 | 438 | 510 | 582 | 653 | 724 | 865 |

| 2,5 | 145 | 173 | 202 | 230 | 258 | 286 | 342 |

| 3 | 163 | 195 | 227 | 259 | 290 | 322 | 385 |